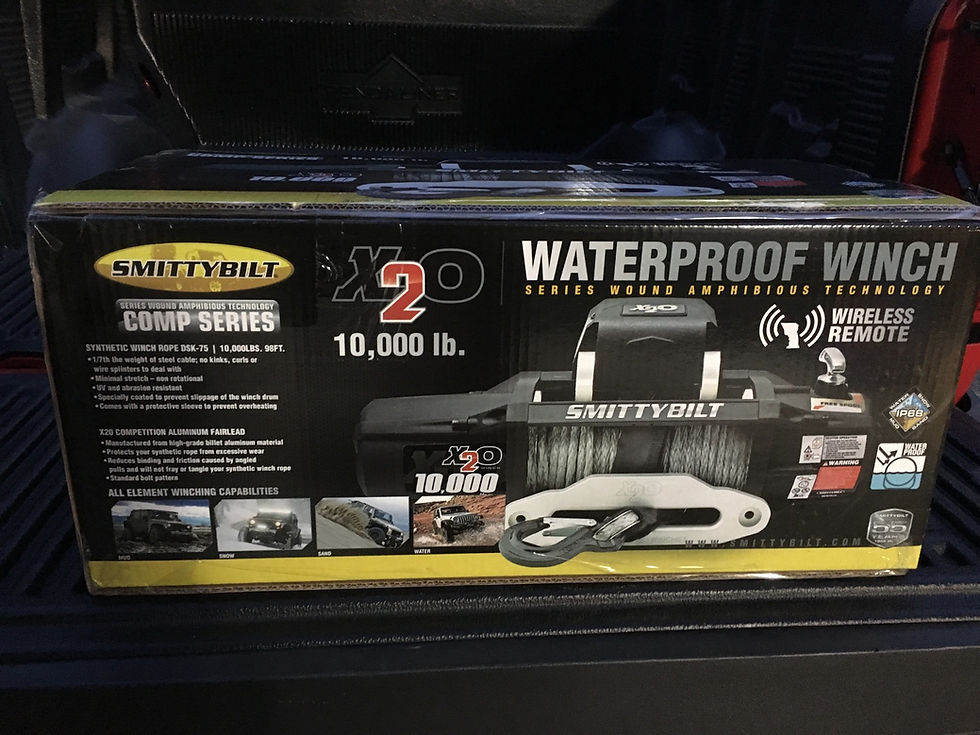

Today I got a winch; the last time I had one it was permanently mounted in my front bumper, but it would have helped me out more if I could have had it in the back. So this time around I plan on mounting it to a cradle. This is also a daily driver, so I figure I don’t need to lug it around 24/7.

Question 1: Where to mount the control box. I’ll probably mount it over the center of the spool, but I was considering mounting it in the engine bay. The biggest problem I see with that, is that there are 3 large wires and one smaller one going to the motor (I am kinda confused as to why 4 wires are needed). I don’t think I have seen any quick connects with 3 or 4 terminals, and that would mean 50% more wire to run 20’ to the rear of the truck. Probably simplest to just keep it with the winch. Anyone have a good reason to remotely mount the control box that makes it worth the effort/cost?

Question 2: Remote control... it comes with a wired/wireless remote control, but I’m also considering that I could wire a switch inside the cabin. For a cradle mounted winch, is it worth the effort to wire a switch? I’m thinking not, but I’d welcome opinions.

I have a few more supplies to get (quick connects, wire, etc.) before I can get it setup, but I’m excited.

I’m in North East King County, but I think I have it handled, thanks for the offer. I work for an electronics company and one of our divisions does high power stuff, so I have been borrowing their crimpers to make my own perfect length cables. I have the front wired up and working, need to find time to measure the cable run to the rear. I also have a solenoid to put in to reduce the chances of a bad electrical short, but I am designing that in with my auxiliary light controller and I need to finding a good spot and enclosure.

Where are you located? If you need any help with mounting I have a small but nice shop and a welder.

I have a Warn cradle mount winch that has control box on the winch with just the power cables to a plug, seems a good concept keeping it all together for transfer ability.

Interesting....I'd be interested to see what the other 2 do.

My new Comeup winch has 6 wires running to it! Plus the red and black power cables! GRRR

WInches are 4 since the field needs to be reversible but the armature polarity stays the same.

4 wires are because it's a series wound DC motor .It has no permanent magnets. 2 wires are for the armature ,2 are for the electromagnetic field

That’s a great point Phil about being able to use it on another vehicle. And I’m not spending another $50 on more 2awg wire.

I’ll have to dig into the schematics if I can find them, or pop the cover off the control box and see if I can make heads or tails of it. My guess is the smaller wire is a sensor of some sort; direction or temperature. Then I guess the reason there are 3 large wires is because they don’t simply swap the polarity, but turn one wire off, and another on, and the ground is always ground...